Abstract

The Non-Intrusive Ultrasonic Level Gauge perfectly solves the problem of measuring the liquid level of the spherical tank without the need to open the tank. The pressure, temperature and medium of the spherical tank have no influence on the detection results.

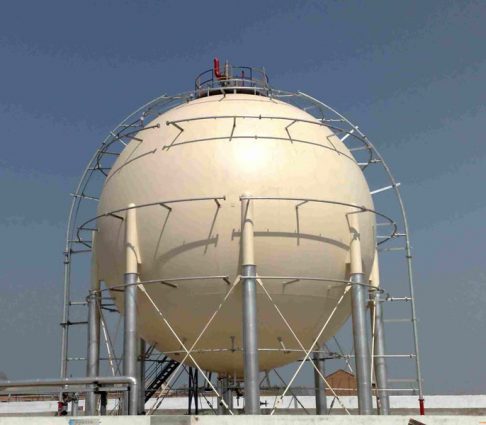

Overview of spherical tank

Spherical container is also called spherical tank, the shell is spherical. It is an effective and economical pressure vessel for storing and transporting various gases, liquids and liquefied gases. It is widely used in chemical industry, petroleum, oil refining, shipbuilding and city gas industry.

Its main advantages over cylindrical containers (Horizontal tank level, Vertical tank) are uniform force; Under the same wall thickness condition, the bearing capacity of the spherical tank is the highest. Under the same internal pressure condition, the wall thickness required by spherical container is only 1/2 of that of cylindrical container with the same diameter and the same material (without considering the corrosion margin). Under the same volume condition, the surface area of the spherical container is the smallest, because of the wall thickness, small surface area and other reasons, it generally saves 30% ~ 40% of the steel than the cylindrical container.

Characteristics of the spherical tank

- The media stored in the spherical tank: liquefied natural gas, isobutane, isopropane, benzene, propylene, propane

- Safety requirements:

- Pressure: high pressure (0.4-1.5)

- Temperature: – 20 ° – 50 °

- Spherical tank material: carbon steel or stainless steel

- Wall thickness: 18 mm to 50 mm

- Diameter: 9 m to 18 m

Difficulties in measuring Spherical Tank:

- Safety factors: because of the spherical tank for high pressure tank, in the process of production, cannot open hole, cannot use contact level gauge, radar level gauge, such as servo liquidometer contact level gauge, at the same time, the early stage of the installation of the Non-Intrusive Ultrasonic Level Gauge to replace after damage, need to production to cease, and at the same time needs to be emptying liquid in the tank, the installation is difficult, high risk coefficient, high cost is not easy to operation.

- Speed of liquid in and out: large quantity and fast speed of feed, unstable feed will have a great impact on liquid level measurement.

- Precipitation thickness: the thicker the precipitation, the greater the gain

- Viscosity coefficient: generally, the dynamic viscosity of the tested medium is required to be less than 10 mPa.S.When 10 mPa.S < dynamic viscosity < 30 mPa.S, the instrument range may be reduced and the blind area will be increased.The dynamic viscosity > 30 mPa.S cannot be measured.(1 mPa.S = 1 cP)

Solutions:

Non-Intrusive Ultrasonic Level Gauge does not need to be opened in the tank hole, and the pressure, temperature, density, viscosity and media is independent, so the choice of external paste type level meter can be a good solution to the above problems.

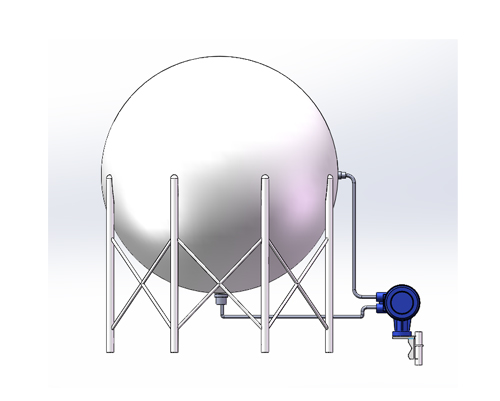

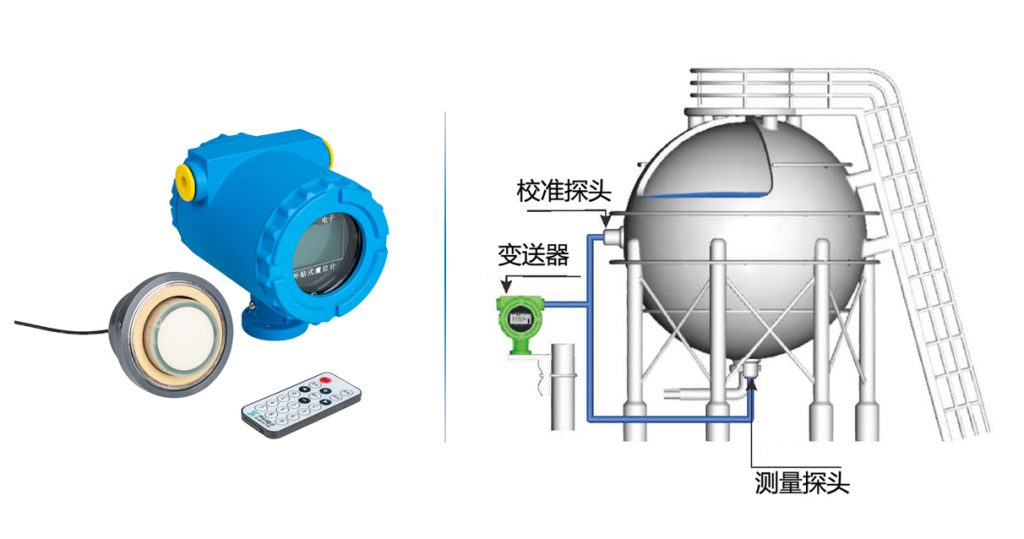

Installation of Non-Intrusive Ultrasonic Level Gauge

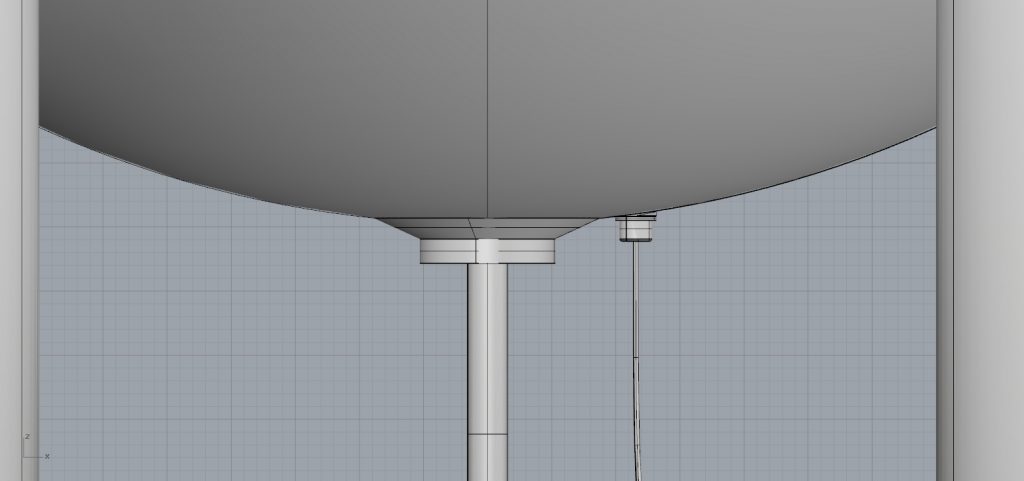

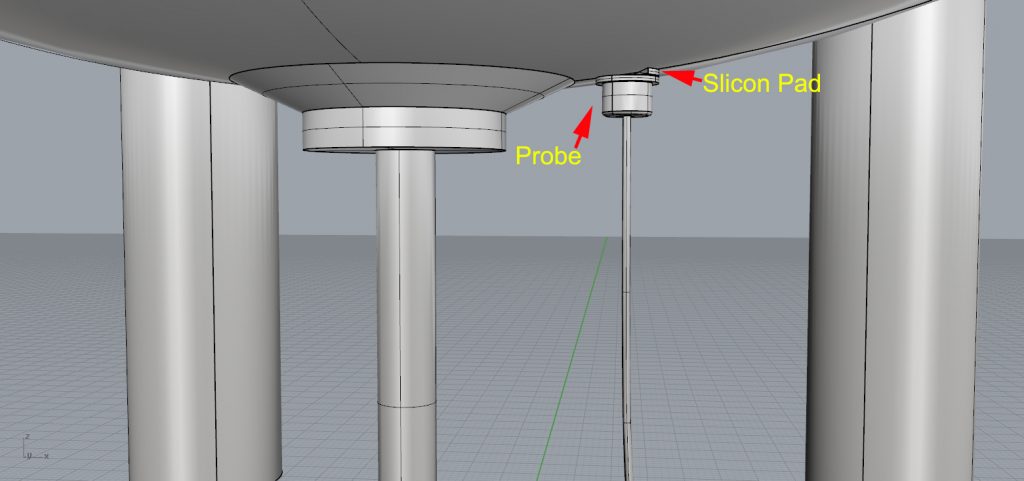

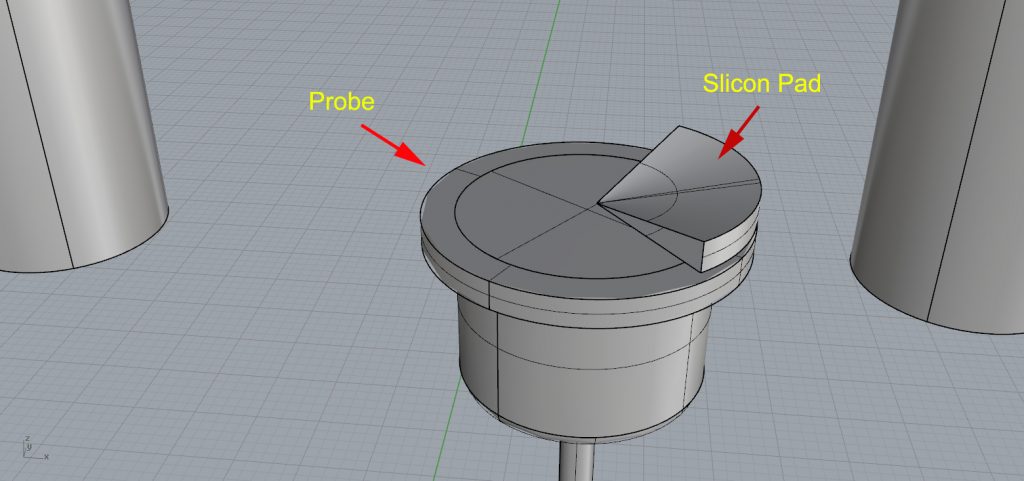

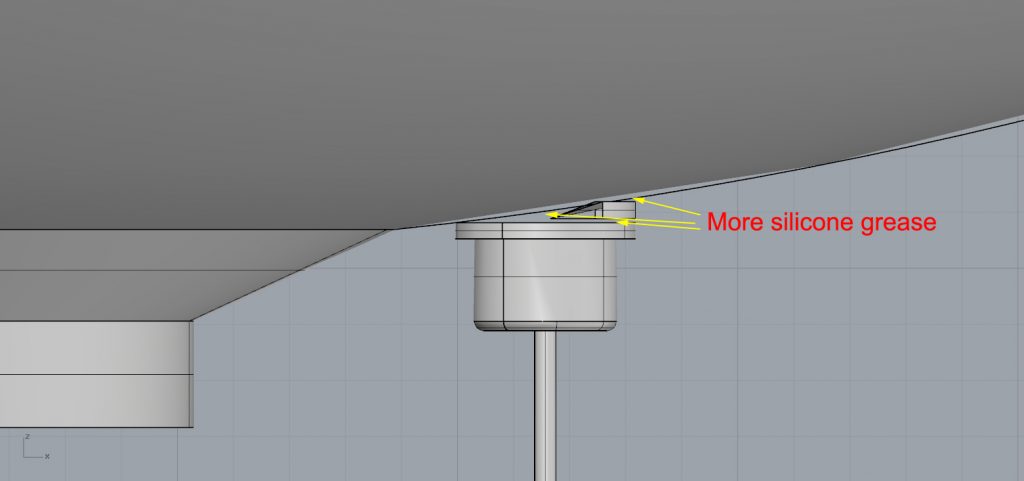

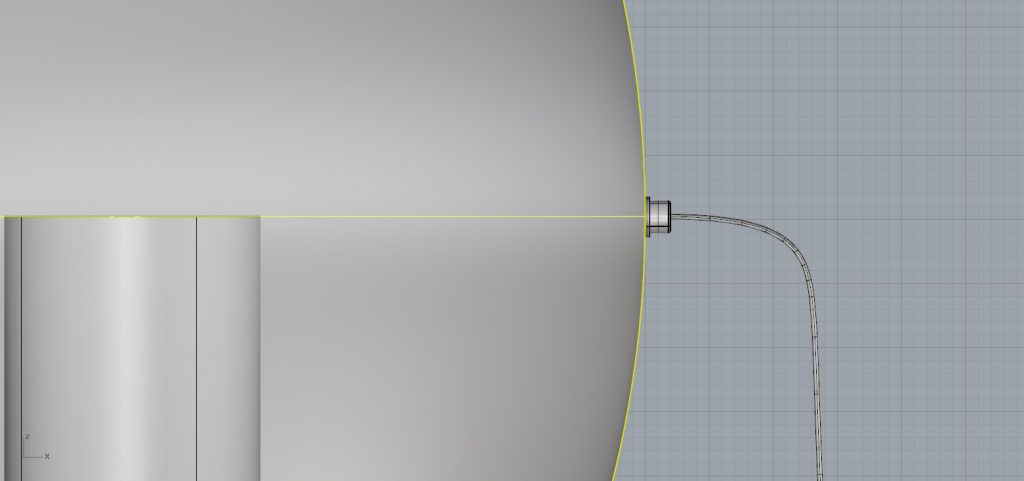

Probe installation: probe installation position tank wall smooth leaking tank wall, probe close to the tank wall, avoid liquid in and out of the mouth, generally installed in within one meter away from the valve at the bottom of the column, due to keep the probe in a horizontal position, so the probe is placed between the tank wall or a film base, make its level (also can be installed in the valve bar).The calibration probe is mounted at the equator of the spherical tank. Not close to the weld.

Instrument debugging: to know the height of tank, the diameter, medium, temperature, and the actual height of liquid level, into the user parameter input height of tank, the default speed of sound (1000), the migration amount (probe installation position and other liquid level meter zero gap, the probe position 100 mm 100 vice plus 100), the waveform interface using the remote control according to the six consecutive 1 set correct frequency (80-400) under the blind area is smaller, the smaller the gain, frequency, the best in finding the best frequency, set up the correct sound velocity, envelope degrees (the larger the range, the greater the envelope smooth waveform).When there is a side calibration probe, it is necessary to enter the menu to set the correct diameter of the side and the height of the side calibration probe, change the measurement mode to the calibration mode, and then enter the waveform interface, change M (measurement) to C (calibration), adjust the correct frequency with the above method, change C (0) to C (1) to start the calibration.No more than half of the liquid level was used with a single probe.

Perfect connection with DCS or SIS

Non-Intrusive Ultrasonic Level GaugeBecause is a two-wire system design, it can be connected with the factory’s DCS system or SIS system. DCS system mainly displays and tracks the liquid level, while SIS system mainly controls the valve for the interlock system.