Fujian Zhongjing Petrochemical Co., Ltd. was invested and constructed by China flexible packaging group in 2012. It mainly uses liquefied petroleum gas (propane) imported from Zhongjing petrochemical terminal,

Propylene is produced by the propane dehydrogenation (PDH) unit, and then polypropylene (PP) is produced from propylene. The project is located in Jiangyin Industrial Center of Fuqing City, covering an area of 2000 mu,

with a total investment of 15 billion yuan, annual production of 1.6 million tons of polypropylene resin, and 1.6 million tons of propane dehydrogenation to propylene monomer, with a total output value of 40 billion yuan.

Fujian Zhongjing Petrochemical Co., Ltd. has 10 Propylene Spherical Tank with a diameter of 15.7 meters. When the plant was built, Kelon radar level gauge and servo level gauge were installed to measure the liquid level.

The company’s Propylene Spherical tank has a special liquid feeding mode, which is directly injected into the bottom inlet of the tank body by the high-pressure pump from the freighter, and the liquid in the tank fluctuates violently,

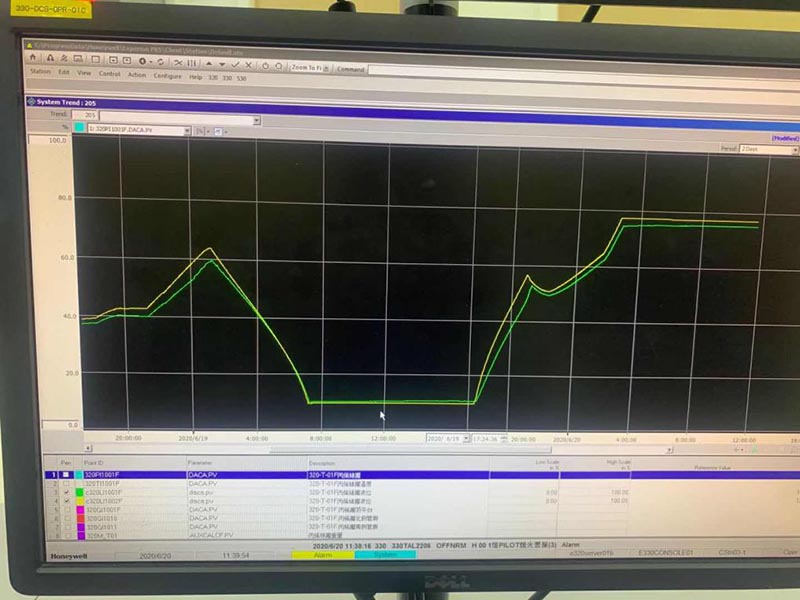

And produce a lot of bubbles. When the liquid level fluctuates, the radar liquid level gauge runs unstably, which causes a huge error in measurement and affects the normal production of the factory.

It happened that the local safety supervision department carried out the acceptance of the emergency interlock transformation (SIS transformation) of the dangerous tank farm.

It required that the liquid level measurement of the Propylene Spherical tank must be done by two out of three, so the user must add a new measurement method. After the repeated demonstration,

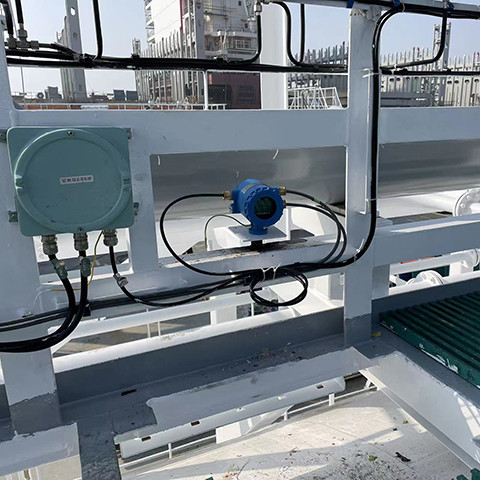

the experts and technicians of Zhongjing Petrochemical Co., Ltd. believe that the installation of the Non-invasive Ultrasonic Level Gauge can be realized without hot work, and there is no need to open a hole in the tank body for hot work,

In this way, security will be greatly improved.

In May 2019, the relevant personnel of Zhongjing Petrochemical Co., Ltd. learned and screened out the two most powerful and most technologically advanced non-invasive level gauge manufacturers in China through peers and other channels,

and put forward trial requirements. The non-invasive liquid level gauge of Shaanxi Shengke and another company were installed on two Propylene Spherical Tanks with the same working conditions for the trial test.

As the liquid in the tank fluctuates violently and produces a large number of bubbles,

The non-invasive level gauge of the other company can not operate stably, and after many times of debugging and maintenance by the manufacturer’s technicians, it still can’t work normally.

The main problems are 1. The gauge stopped work when entering the liquid and does not track the liquid level; 2. The error is huge and the liquid level can not be measured; 3. The liquid level jumps disorderly and randomly.

SKE two-wire non-invasive liquid level gauge has been used in Fujian Zhongjing Petrochemical Propylene Spherical Tank for several months. It can accurately measure and track the liquid in and out of the spherical tank,

and the operation is stable, which perfectly solves the problem of liquid level measurement in and out of the liquid. Especially in terms of measurement accuracy,

The error of measurement results between the non-invasive level gauge and the field servo level gauge of sonic electronics is controlled within one-thousandth, fully meeting the requirements of customers for measurement accuracy.

At present, the customer has replaced the radar level gauges of three spherical tanks with those of Shaanxi Sound Technology Co., Ltd., and plans to replace the radar level gauges installed on the remaining seven spherical tanks.

The relevant personnel of the Zhongjing petrochemical company highly appraised the two-line non-invasive level gauge developed and produced by Shaanxi Sound Technology Co., Ltd., and Shaanxi sound technology once again changed the user’s understanding of outside sticking liquid level meter.

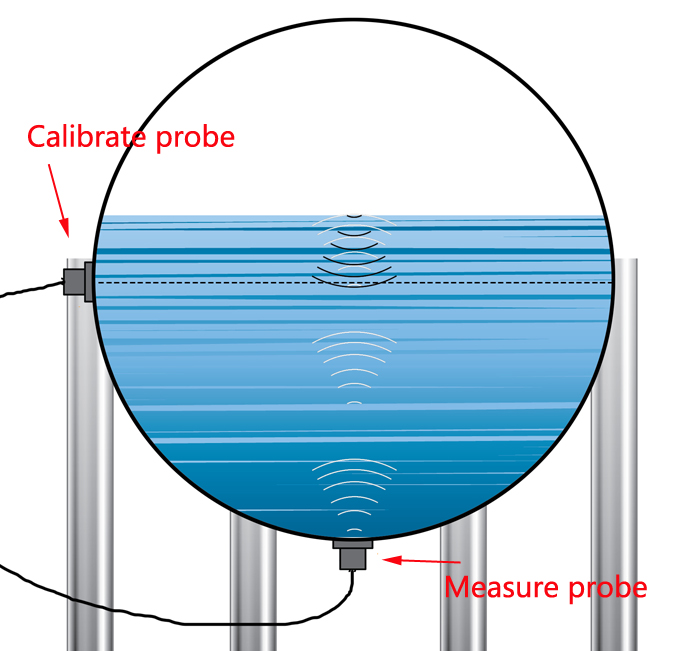

The liquid level gauge developed and produced by SKE breaks through the traditional installation mode of open tank contact, which can realize the real non-contact measurement of the liquid level in the closed container.

It is easy to install and can be installed online without opening the container. It can accurately measure the liquid level of various toxic substances, strong acids, strong bases, and various pure liquids in high temperature and high pressure closed containers. The liquid level gauge has no special requirements for the material of liquid medium and container and adopts an explosion-proof design to meet the explosion-proof requirements. It can be widely used in various working conditions.