Liquid ammonia is a colorless, pungent smell of liquid, has a certain corrosive. The density of liquid ammonia is greatly affected by temperature. Ammonia is an important chemical raw material. In order to facilitate transportation and storage, ammonia gas in the gaseous state is usually pressurized or cooled to obtain liquid ammonia. Liquid ammonia is mostly stored in pressure-resistant cylinders or steel tanks and cannot coexist with acetaldehyde, acrolein, boron and other substances. Liquid ammonia is widely used in industry, corrosive and volatile, so its chemical accident rate is very high.

A spherical tank is a large capacity, pressure spherical storage vessel, widely used in petroleum, chemical, metallurgical and other sectors, it can be used as liquefied petroleum gas, liquefied natural gas, liquid oxygen, liquid ammonia, liquid nitrogen, and other media storage containers. It can also be used as a storage tank for compressed gases (air, oxygen, nitrogen, city gas).

The use of a spherical tank can greatly reduce the consumption of steel, generally save 30% ~ 45% of steel; In addition, the spherical tank occupies a small area, the amount of foundation works is small, can save the land area.

The liquid level of a liquid ammonia spherical tank in a factory USES the differential pressure transmitter as the liquid level gauge on the liquid ammonia spherical tank. In the course of many years of use, the measurement error is large and the maintenance is inconvenient, especially when adding liquid ammonia into the spherical tank, the measurement error is greater.

Later, a set of magnetic flip plate field indicator was added, and the liquid level indicated by the transmitter did not correspond to the liquid level indicated in the field.

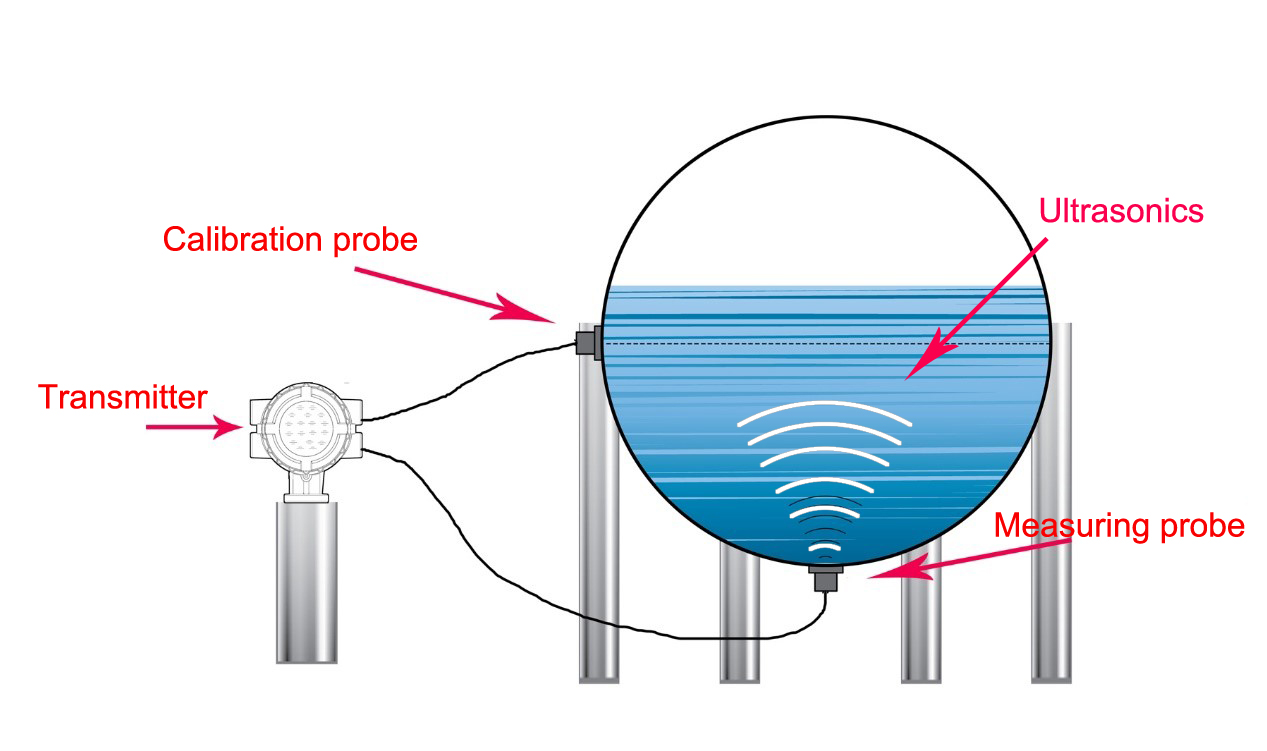

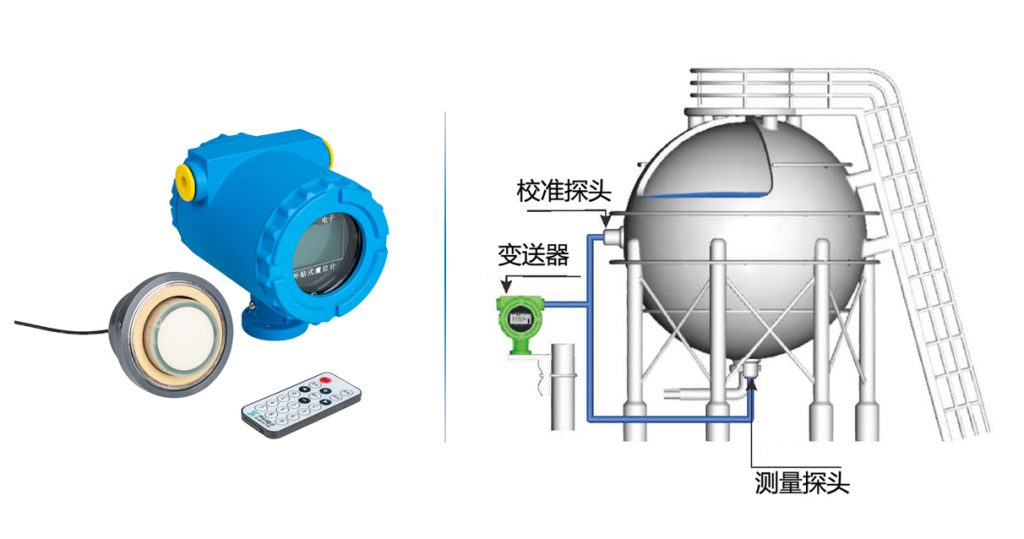

In recent years, SKE has been applied to the Spherical tank with Non-Intrusive Ultrasonic Level Gauge. The instrument is installed without opening and hot fire, which is accurate in measurement, convenient in installation and has a good effect in use. Simply place the probe on the outside of the tank bottom to measure.

Non-Intrusive Ultrasonic Level Gauge Automatic calibration function: when the temperature and composition of the liquid change, it will affect the propagation speed of sonar signal in the liquid, bringing measurement error.

In order to ensure the instrument measuring precision, can be in spherical tank calibration position with the equator diameter probe, according to the diameter of the known time is obtained by the received signal, and the actual sonar in the liquid is spread, the liquid level meter liquid level measurement results are within the host compensation correction, eliminate the liquid temperature and the influence of composition change on measuring precision.

Non-Intrusive Ultrasonic Level Gauge is used in the superiority of liquid ammonia spherical tank.

- Two-wire external level gauge: not only reduces power consumption, more safety but also reduces wiring and installation costs.

Stable performance: instruments and probes without mechanical moving parts, and strictly sealed, reliable and durable, almost maintenance-free. - Minimal installation: the most convenient and economical installation and maintenance.

No holes in the container, no flanges, no connecting pipe, both old and new containers can be easily installed. - Automatic commissioning, automatic calibration: no manual calibration is required for installation, commissioning and use.

It is very convenient and keeps high precision forever - Wide application range:

When measuring poisonous, corrosive, pressurized, flammable, explosive, volatile and leaky liquids, the measuring head and instrument are outside the container, so the installation, repair, and maintenance operation should not touch the liquid and gas in the tank, which is very safe. There is no possibility of leakage even if the instrument is damaged or under repair. - Can be used in a variety of harsh environments.

- A liquid that can be measured at any pressure.

- It can measure the most corrosive liquid.

- The highly toxic liquid can be measured.

- The inflammable, explosive, leaky, and contaminated liquid can be measured.

Report on the use of Non-invasive Ultrasonic Level Gauge for installation of Hebei Donghua Liquid Ammonia Storage Tank

Hebei Donghua Jiheng Co., LTD. (hereinafter referred to [...]

What level gauge will be used for the liquid ammonia tank?

Liquid ammonia is a colorless, pungent smell of liquid, [...]

The Non-intrusive ultrasonic level gauge was successfully connected to SIS safety interlock system of an energy company in Hancheng, Shaanxi Province

An energy company in Hancheng, Shaanxi Province is mainly [...]

18.2m liquid ammonia spherical tank was successfully installed with Non-Intrusive Ultrasonic Level Gauge

18.2m liquid ammonia spherical tank was successfully installed with [...]