The pesticide industry is a kind of industry with long production process, complicated technology, and high product quality standard.

Many kinds of raw and auxiliary materials are needed for each drug, and many raw materials and intermediates in the production process are inflammable, toxic, or corrosive. Its production process has strict requirements for dustproof, explosion-proof, waterproof, sanitary grade and other instrument equipment.

In addition, due to the high added value of drugs and the high precision requirements for filling and filling, the production workshop must have appropriate personnel, workshops, equipment and testing instruments, and build a real-time communication and data platform integrated with the production process control and production management system, so as to realize the whole process of intelligent production.

Liquid chlorine is often used in the production process of a pesticide manufacturer in Inner Mongolia.

Liquid chlorine is yellow liquid, the boiling point 34.6 ℃, melting point 103 ℃, under ordinary conditions of vaporized into gas, inhaled can severe poisoning, has the intense stimulation and corrosive, when mixed with other flammable gases in the sun burning and explosion, chlorine is very lively material, can react with most elements (or compound). The maintenance of liquid chlorine storage tank with built-in level gauge is complicated and dangerous, and the customer needs the level gauge free of maintenance. According to the customer’s demand, SKE Department provides customized solutions of Non-invasive Ultrasonic Level Gauge, which can meet the requirements of the pharmaceutical and pesticide industries for automatic control of liquid level and temperature.

SKE Non-invasive Ultrasonic Level Gauge has the advantage in liquid chlorine tank level measurement:

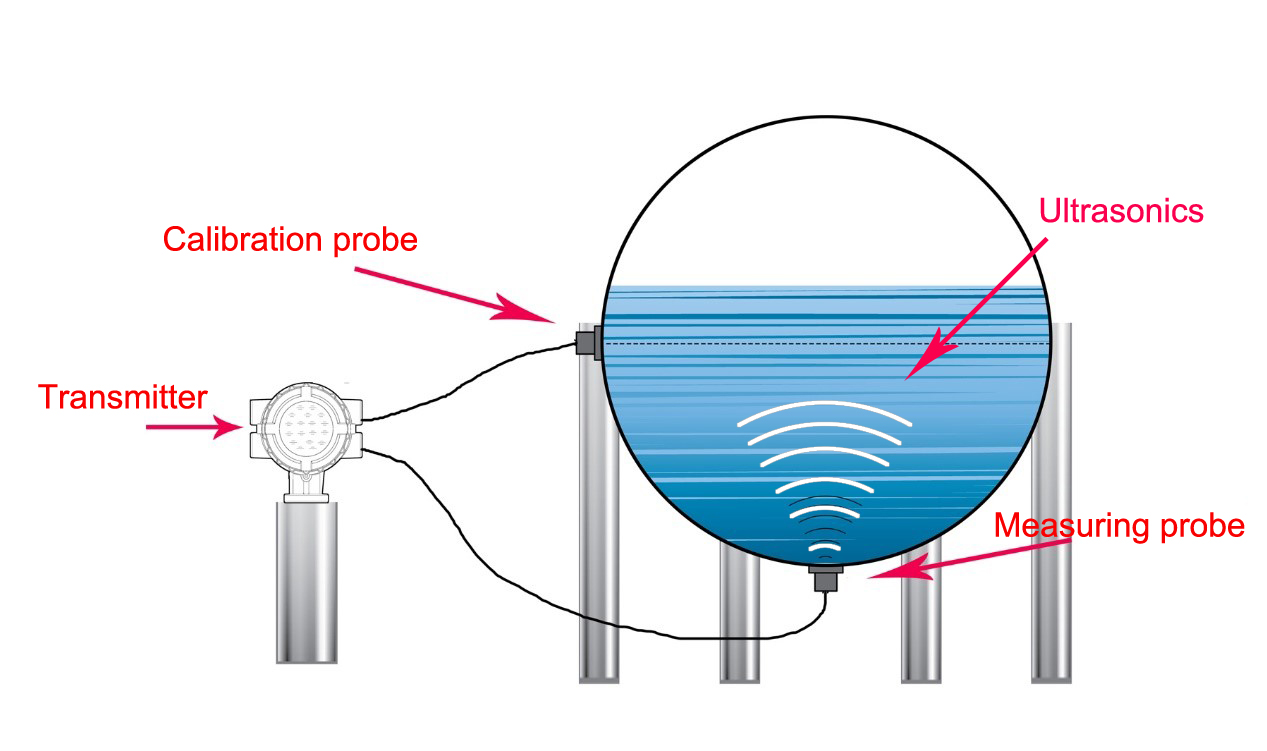

1. Externally mounted liquid level meter adopts sonar technology, which does not need mechanical parts, easy to install and free of maintenance;

2. Compared with laser ranging technology, the operation is simple and the price is affordable;

3. Fixed point and continuous position measurement can be set;

4. The tank can be automatically converted from liquid level to volume;

5. LCD with backlight can be displayed according to standard engineering units;

6. Non-contact measurement method is adopted. External sonar sensor (probe) is installed without valves, connecting pipes, joints, holes and contact with liquid chlorine in horizontal tanks.

External Level Transmitters Application in Liquid Chlorine Measurement

The control and measurement of level and flow play [...]

Non-Invasive Tank Level Measurement on Liquid Chlorine

One of our clients in fine chemical area. The [...]

The application of Non-invasive Ultrasonic Level Gauge in liquid chlorine storage tank in Pesticide industry

The pesticide industry is a kind of industry with [...]