Hebei Donghua Jiheng Co., LTD. (hereinafter referred to as Donghua Jiheng) was established in 2005, located at No. 10, Jheng Road, Industrial New District, Hengshui city, Hebei Province.The company’s predecessor Donghua Chemical was founded in 1979, is China’s first research and production of glycine manufacturers.Donghua Jiheng owns 5 industrial grade amino-acetic acid production lines, which produce 90,000 tons of amino-acetic acid per year, and the byproducts include ammonium chloride and organic compound fertilizer, 100,000 tons each.Phase III project will be carried out in 2014, focusing on the expansion of industrial grade amino-acetic acid production line with an annual output of 60,000 tons, by which time the annual output of industrial grade amino-acetic acid will reach 120,000 tons.

The existing pressure difference liquid level gauge and magnetic flip plate liquid level gauge in the liquid ammonia tank on site all have the problem of inaccurate liquid level measurement. The pressure difference liquid level gauge is inaccurate because the pressure film attached to the contactor is too thick for too long.

Liquid ammonia medium is greatly affected by temperature, which is seriously gasified when the temperature is high, and magnetic flip plate liquid level gauge will appear when the temperature is too high at noon, the phenomenon of magnetic flip plate full range will occur.

At the early stage of installation, accurate liquid level can be measured by differential pressure level meter and magnetic flip plate liquid level meter. However, with the gradual occurrence of problems in differential pressure liquid level meter and magnetic flip plate liquid level meter, it is impossible to timely measure accurate liquid level in the tank, and the safety risk is becoming higher and higher.

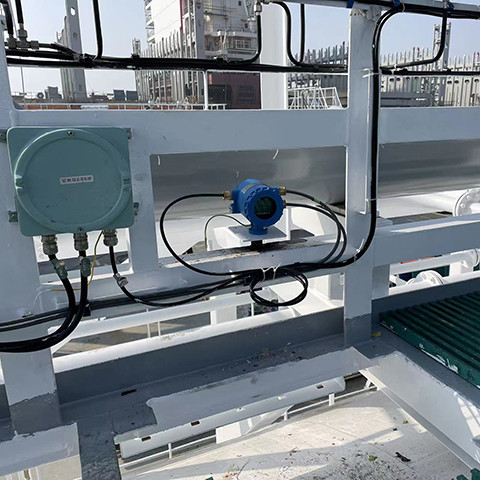

In June 2018, SKE installed a Non-invasive Ultrasonic Level Gauge for Donghua Jheng Liquid Ammonia storage tank for trial. After two months of trial, the stable operation, normal accuracy, high temperature influence and small, met the requirements of field use.

Sound in October 2018, SKE branch for the Donghua JiHeng chemical install 10 type level gauge is stuck outside to solve “the tank liquid level accurate measurement and reduce security risks exist, the scene in order to guarantee the accuracy of the level of, in the storage tank at each end of installing a type level gauge is stuck outside, at the same time the real-time monitoring of two groups of stick type level gauge on the tank operating conditions.

After data tracking for half a year after installation, the two groups of Non-invasive Ultrasonic Level Gauge in the on-site liquid ammonia storage tank operated normally, and the liquid level difference between the two groups was less than 1cm and the operation was stable.

SKE research and development of the production of external paste type liquid level gauge can be liquid ammonia, liquid chlorine, concentrated sulfuric acid, propylene and other flammable, explosive, strong corrosive medium to realize the real non-contact measurement, without the need to open a hole can be sealed storage tank liquid level measurement, safe and reliable, welcome your call consultation