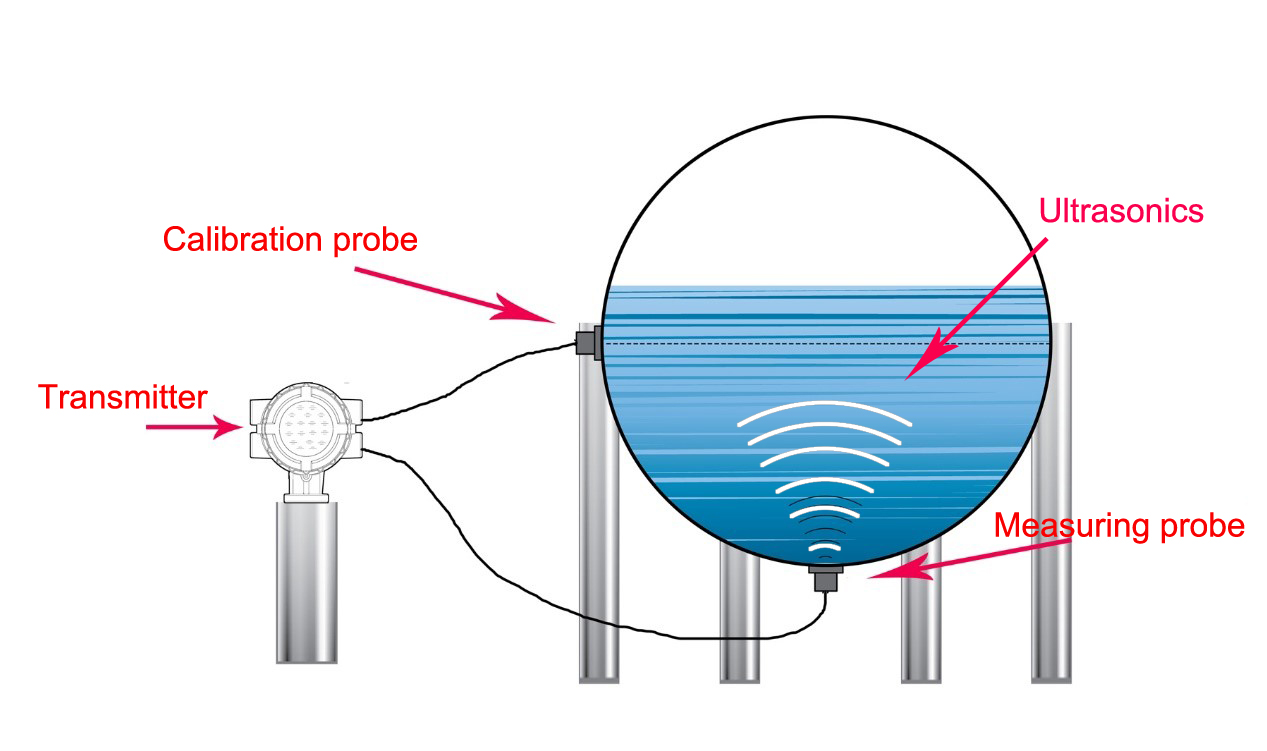

Non-invasive Ultrasonic Level Gauge is a new type instrument which adopts sonar ranging principle to measure the liquid level of storage tank. Truly non-contact equipment that can measure the liquid level on the outside of the tank. There were papers and instrument models back in the 1970s that were supposed to measure liquid fuel in rockets, but the technology was limited to the level of development of piezoelectric ceramics and computer processors at the time, and no industrial product was available. In the 1990s, scholars in Northwestern Polytechnical University began to conduct relevant theoretical research, and the domestic externally affixed liquid level meter was only published at the beginning of this century, and gradually applied in the market.

China’s Non-invasive Ultrasonic Level Gauge (External stick level gauge) products in the field of research and application has been in the forefront of the world, so the level of domestic research and development at this stage basically represents the global level.

However, the research and development level of some domestic manufacturers is relatively low, and the product performance is relatively poor, which is not enough to support the external stick type liquid level gauge to become the mainstream liquid level gauge products.

But, With the rapid development of electronic technology and signal processing technology in recent years, the measurement technology of liquid level measuring instrument has experienced the development process from mechanical to mechatronics, and then from mechatronics to automation.

According to some weak links of the Non-invasive Ultrasonic Level Gauge, each of the devices is broken:

- The first two-wire system of externally affixed liquid level gauge.

Not only lower power consumption, more secure, but also lower wiring and installation costs. - Higher stability.

By using advanced electronic technology, Shannxi Sound decisively adopts ARM-based chips with stronger computing power, which not only improves the performance of the product, but also reduces the volume of the entire product and makes it more widely used.

It is more powerful and more integrated than 51 single chip microcomputer which is used as the core of calculation.

Even when the tank is in and out of the liquid (liquid level fluctuation) can be measured stably. - Smaller blind areas.

The high sensitivity ultrasonic transducer (probe), the bandwidth is larger, together with the powerful chip computation ability, may precisely control the ultrasonic frequency and the pulse number, from the frequency domain and the time domain two dimensions control and reduces the blind area. - High precision.

Accuracy is affected by the speed of sound and chip computing speed.

Shaanxi Department of sound through diameter calibration and temperature calibration and other technical ways to calibrate sound velocity. - Complex conditions such as precipitation.

High bandwidth and high sensitivity probe can automatically match the frequency according to the tank thickness and precipitation thickness, even if the tank has precipitation will not affect the measurement results. - Easier installation and debugging.

Exclusive design of automatic debugging function.

After years of experience accumulation, as well as continuous upgrading and transformation of externally mounted liquid level gauge, the sound products are more stable and more accurate.