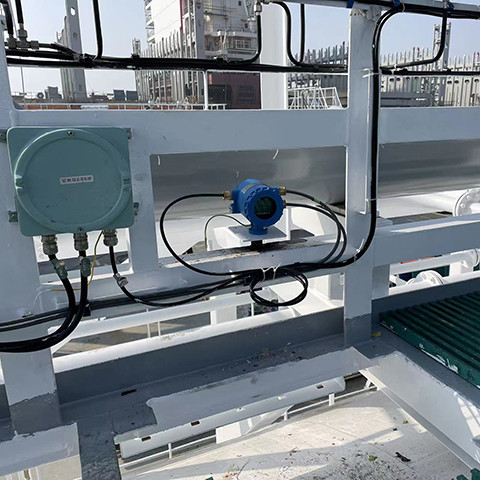

Project Description

Non-invasive Level Gauge

SK-WY02

BENEFITS

No electrical power parts inside the tank, 100% safe

Max Measuring Range 30meters (100ft)

No downtime/empty tank during installation

No tank break-in; Non-drilling; No leakage risk

No moving part, No maintenance

Operated by a remote control, No PC, No Oscilloscope

Local display + Remote output (4-20mA/RS-485)

Best for flammable, toxic, vaporized liquid.

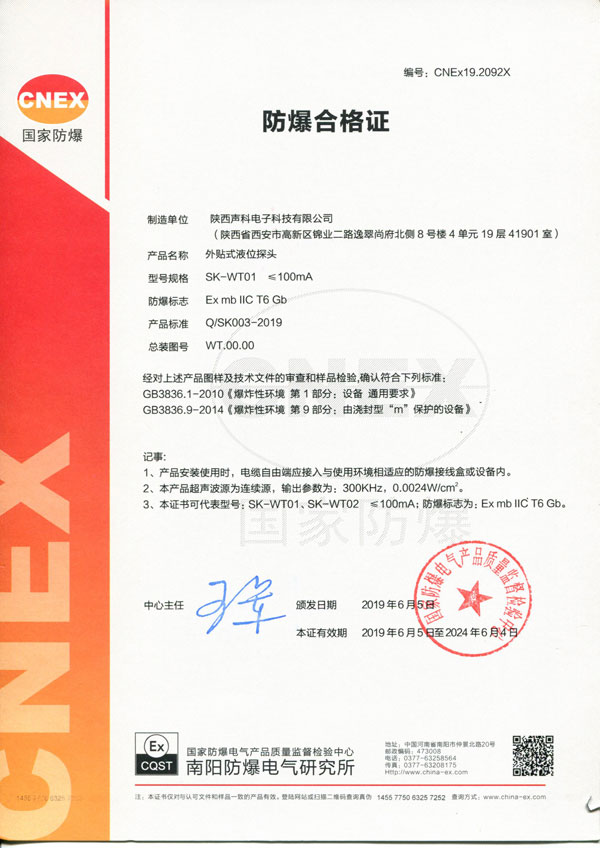

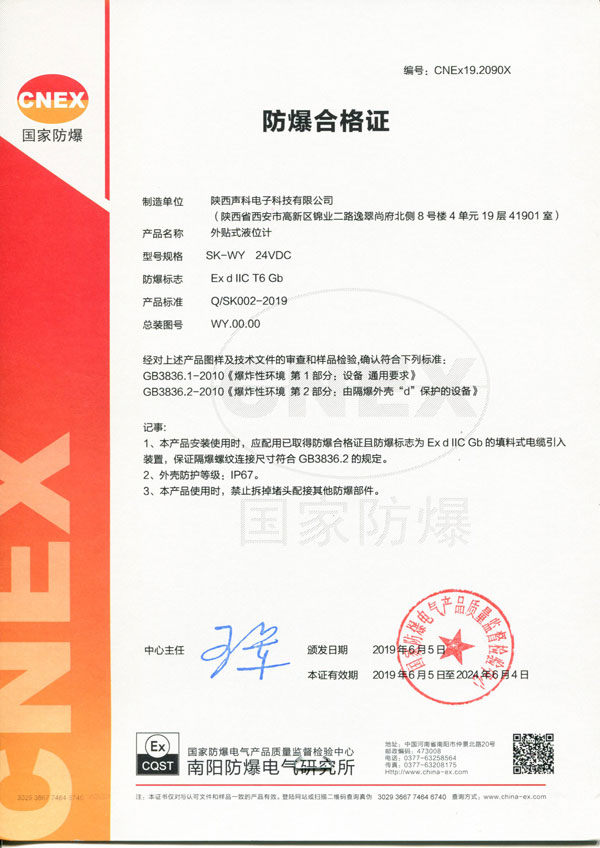

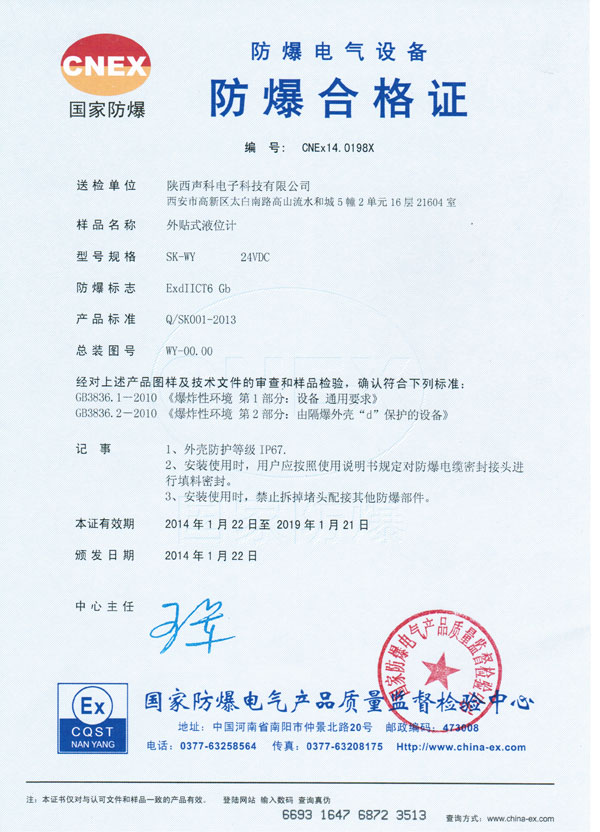

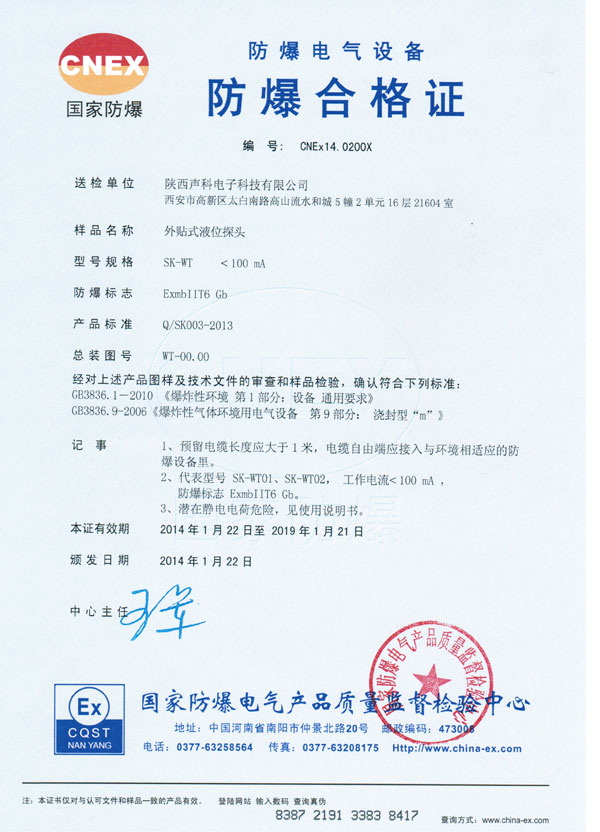

ATEX, CE, SIL, ISO 9001

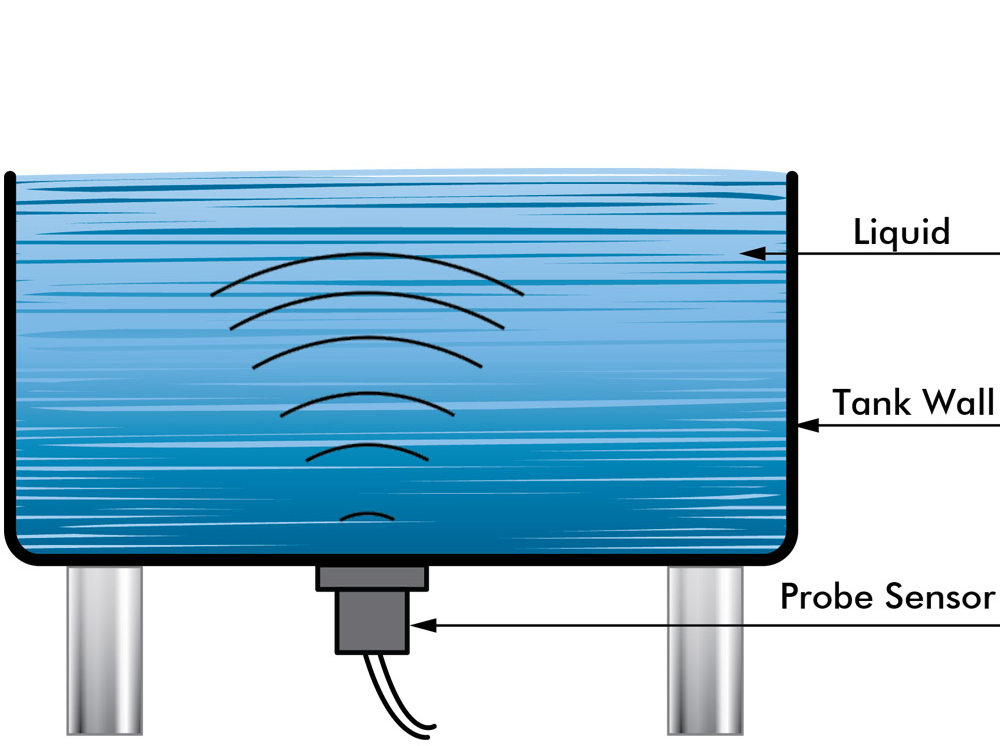

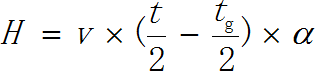

Principle

Whether your tank management application is best served by Radar, Servo, or Ultrasonic, SKE offers advanced level measurement solutions:

– Non-invasive Sensing Technique

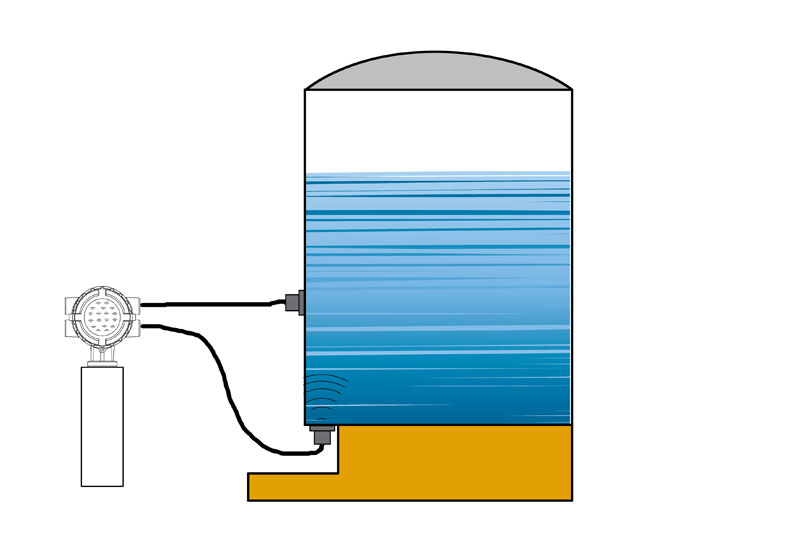

This Non-invasive Level Gauge adopts the principle of Sonar Ranging.

When the probe sensor is bonded to the bottom wall of the tank, a sound wave travels through the tank/medium and reflects back from the liquid surface.

The sensor is responsible for emitting and receiving sound waves, then transmits them to the system, and calculates the height (H) of the liquid, from the time (t) taken for the signal to be received.

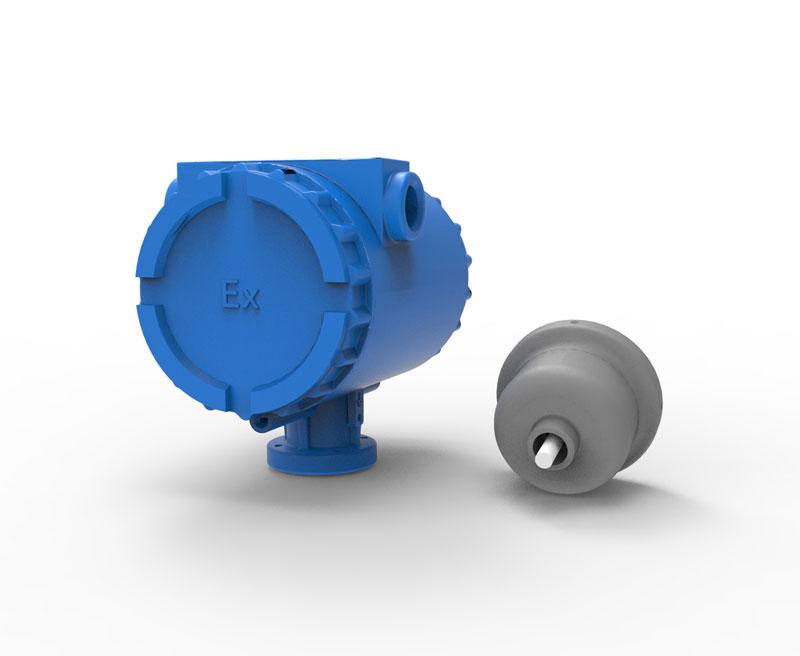

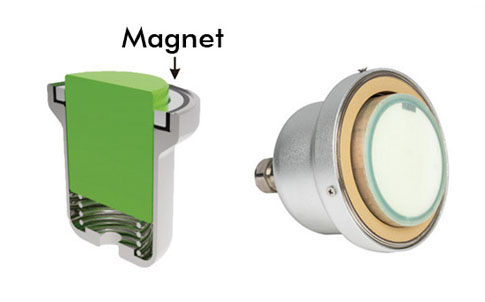

Probe Sensor

SKE self-developed probe sensor applies piezoelectric ceramic materials.

The magnetic ring is setting around the sensor. Pretty easy to install on a ferromagnetic material tank (exp: carbon steel).

For a non-ferromagnetic material tank(exp: stainless), the steel adapter board with the package would help to fix it.

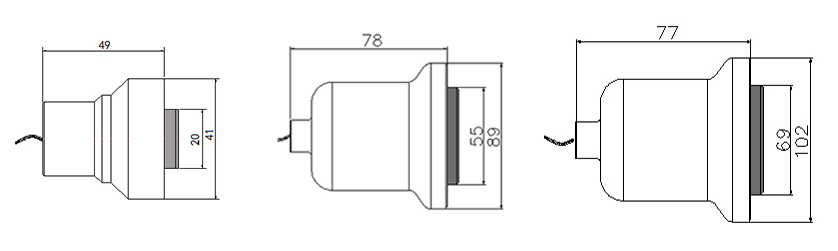

According to different working conditions, measuring range, tank type/size, there are three types of probe sensors with different sizes and powers to be selected

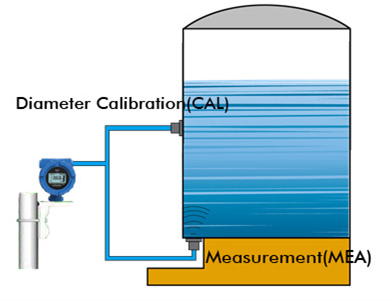

Measurement (MEA) & Calibration(CAL, TEMP)

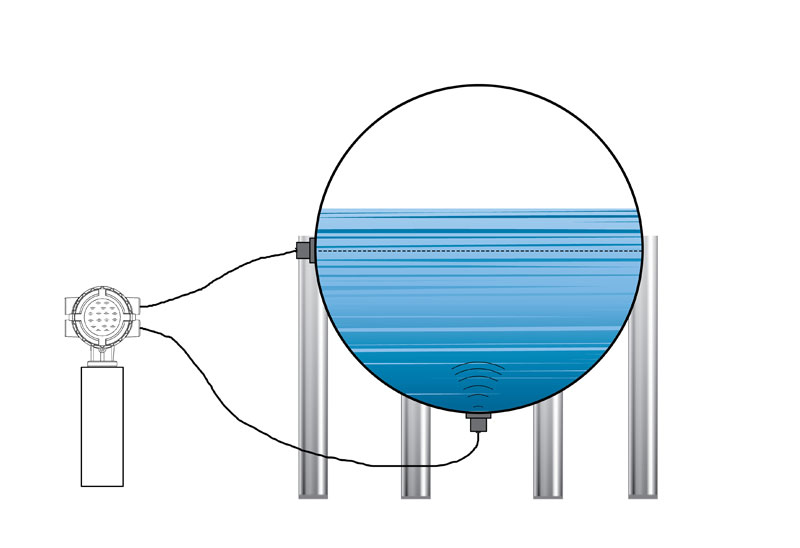

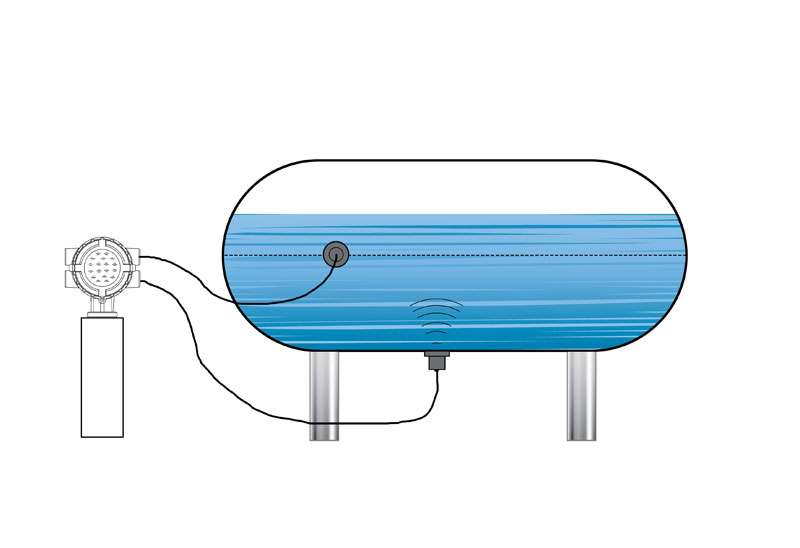

Generally, a tank monitoring case often requires two probe sensors at a time:

– The one on the bottom for level measurement, called Measurement Sensor (MEA)

– The other is the Diameter Calibration Sensor(CAL), which bonded on the sidewall, to continuously calibrate the real-time sound velocity and update to the Transmitter.

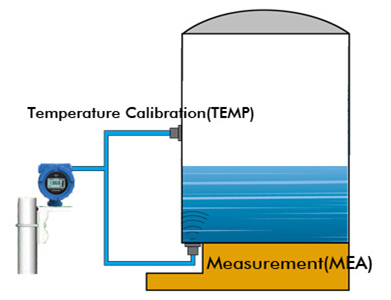

In some practical applications, the sound velocity would be varied due to environment/liquid temperature change. The accurate sound velocity value would be a key point for the level measurement result:

When the level inside is lower than the CAL sensor position, Diameter Calibration would be off work.

At that time, Temperature Calibration(TEMP) would be automatically turned on. It keeps recording the temperature change, transmits data to the software algorithm, then obtains accurate measurement results.

Two Wire Non-invasive Level Gauge

The Non-invasive Level Gauge is in use everywhere where the level of liquids in tanks has to be measured continuously and contactlessly. Application possibilities for radar gauges can be found in almost all areas of industry. Sewage treatment plants and water purification plants in particular, but also other environmental engineering facilities as well as power generating stations now rely on cost-effective radar sensors for continuous level measurement.

Measured substance

In general, the dynamic viscosity of the measured medium is required to be less than 10 MPa. S. When 10 MPa. S < dynamic viscosity < 30 MPa. S, the measure range may be reduced and the blind area may be increased. It cannot be measured when the dynamic viscosity is > 30 MPa. S. (1 MPa. S = 1 CP). There should be no dense bubbles in the liquid; there should not be a large number of suspended substances in the liquid, such as crystals; there should not be a large number of sedimentary substances in the liquid, such as mud and sand. The temperature of the measured medium shall be within – 50 ℃ ~ 100 ℃.

| Butadiene | Propylene | LPG | Propane |

| Liquid ammonia | Methyl alcohol | Methylbenzene | Butadiene |

| 98% sulfuric acid | Diesel | Gasoline | Naphtha |

| Liquid chlorine | Iso-butane | Epoxypropane | Acetone |

| Sulfuretted hydrogen | Styrene | N-butane | Xylene |

| Silicon tetrachloride | Tert-butylamine | Chloroform | Acetaldehyde |

| Hydrogen fluoride | Hydrofluoric acid | Butane | Hydroxy nickel |

Technical specifications

| Max Measuring range | 30 m |

| Measuring error | ±1%FS |

| Transfer volume | ±100m |

| Frequency range | 20k-400k |

| Signal output | 4~20 mA, MAX 500Ω |

| Communication | RS-485, IR |

| Environment temperature(transmitter) | -20℃~+70℃ |

| Environment temperature(sensor) | -50℃~+85℃ |

| Ambient humidity | (0~100%)RH |

| Explosion-proof | Exd II CT6 |

| Enclosure protection grade | IP67 |

| Power supply | DC 24V |

| Cable length option(sensor to the transmitter) | 5m,10m,15m,20m,25m,30m |

| Weight(transmitter) | 2.5KG |

| Size(transmitter) | 217mm(length)*160mm(width)*185mm(height) |

| Base hole diametter | 6mm |

Documentation