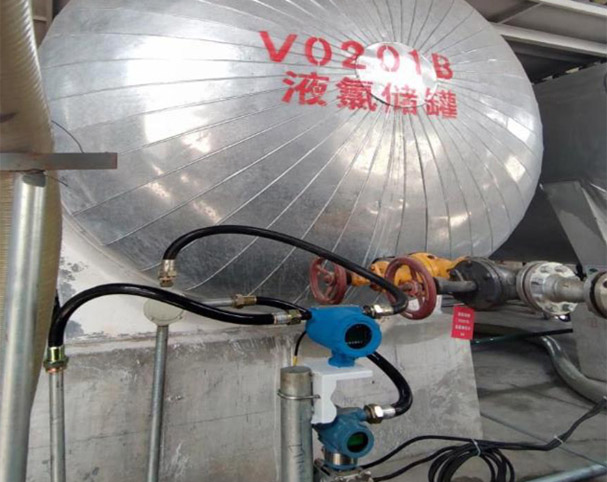

The control and measurement of level and flow play an important role in industrial production, In the liquid chlorine production process, the chlorine measuring tank requires to be frequently changed, and the packaging tank does the repeated filling job. In the meantime, as a highly toxic substance, chlorine in the tank has to be strictly leak-proof to prevent harm to operators.

Therefore, the safety and reliability of the chlorine level instrumentation request to be particularly critical.

One of our Clients in Ningxia, China, a vibrant young company that engages in the production of Sulfur dioxide, thionyl chloride, sodium bisulfite, hydrochloric acid. Both in process control and finished product storage require accurate level measurement.

The magnetic level indicators were applied before, however, the accumulated precipitation in liquid chlorine affects the accuracy of the measurement, and even makes indicators out of work.

Level meter replacement would be costly in terms of time, money, and risk of leakage.

Therefore, they were in urgent find us, and require a different type of level measurement solution, both safe and reliable for the liquid chlorine.

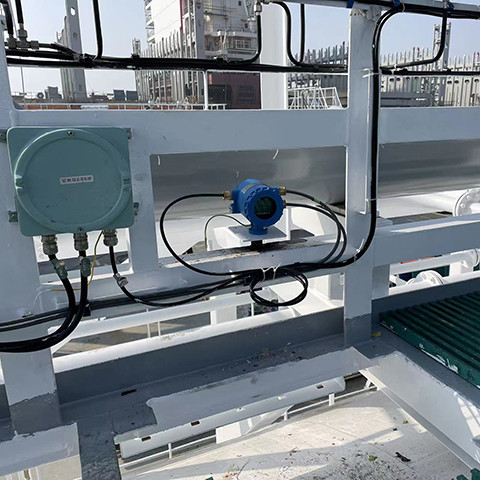

The non-invasive level transmitter provided by SKE adopts a sonar ranging principle, which measures the liquid level without tank break-in. This solution avoids the indicator block, hard to clean & maintenance that frequently appears on the magnetic level meters.

These non-contact level transmitters provide long-time accurate results without leakage risk. There was no shutdown during installation, bringing significant time and cost savings for our clients.