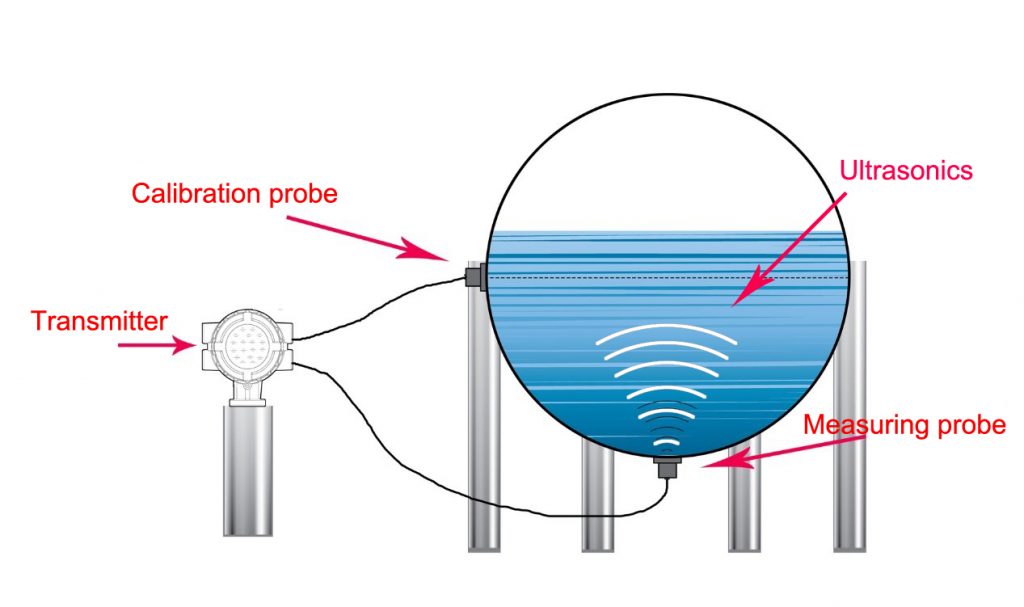

The Non-invasive Ultrasonic Level Gauge is based on the principle of ultrasonic distance measurement. The measuring probe is installed on the outer wall of the bottom of the container. The reflection and transmission characteristics of ultrasonic are used. As shown in the figure.

When the ultrasonic emitted by the probe is propagated to the bottom wall of the container, the first reflection echo will be generated due to the change of the propagation medium. After that, the ultrasonic wave will continue to propagate in the measured liquid medium. When it is propagated to the gas-liquid interface, the propagation medium will change again and generate the second reflection echo.

Assuming that the time difference between the first reflection echo and the second reflection echo is T, according to the ultrasonic wave propagation velocity c in the measured liquid, the liquid level value L in the container is equal to c *T/ 2

The advantage of this liquid level measurement method is that there is no need to make holes or install flanges on the tested container, and the internal liquid level information can be obtained directly from the outside of the container, which truly realizes the non-intervening liquid level measurement.

However, the measurement accuracy of this method is closely related to the installation position of the probe, and the more vertical the ultrasonic propagation direction is with the liquid level under test, the better the measurement effect will be.

In addition, in the measurement process, ultrasonic wave needs to pass through the container wall and the measured liquid, which is easily affected by the factors such as the sediment at the bottom of the container, liquid bubbles and liquid impurities, etc., and there are many limitations in the practical application process.

According to the physical characteristics of ultrasonic waves, the propagation velocity of ultrasonic waves in the medium is easily affected by the temperature of the medium. In the practical application, in order to obtain higher measurement accuracy, the sound velocity needs to be corrected and compensated.