Non-Invasive Level Gague Application

LPG (or propane) can be measured in numerous ways due to its properties, including volume (meter), flow, weight, and pressure. In residential gas applications, LPG is mostly delivered in metal cylinders(usually less than 45kg). While industrial plant or gas distributions, their storage tanks volume are huge.

The most general gauge type provided by the tank system is the Float. The float position is changed with the propane liquid, then display as a percentage for the controller.

The price of float level gauges are not expensive, however, two problems that frequently occur on them:

– Damage caused by moving parts and mechanical structure;

– Inconvenient maintenance/renewal;

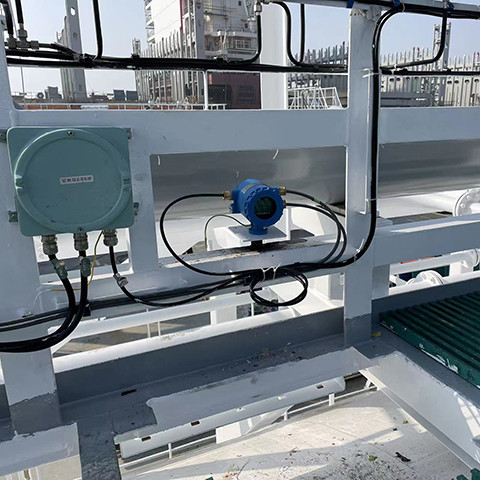

Here is the propane tank level/volume monitoring application in Mexico, by applying the non-invasive solution, clients clearly obtain their tank and propane condition.

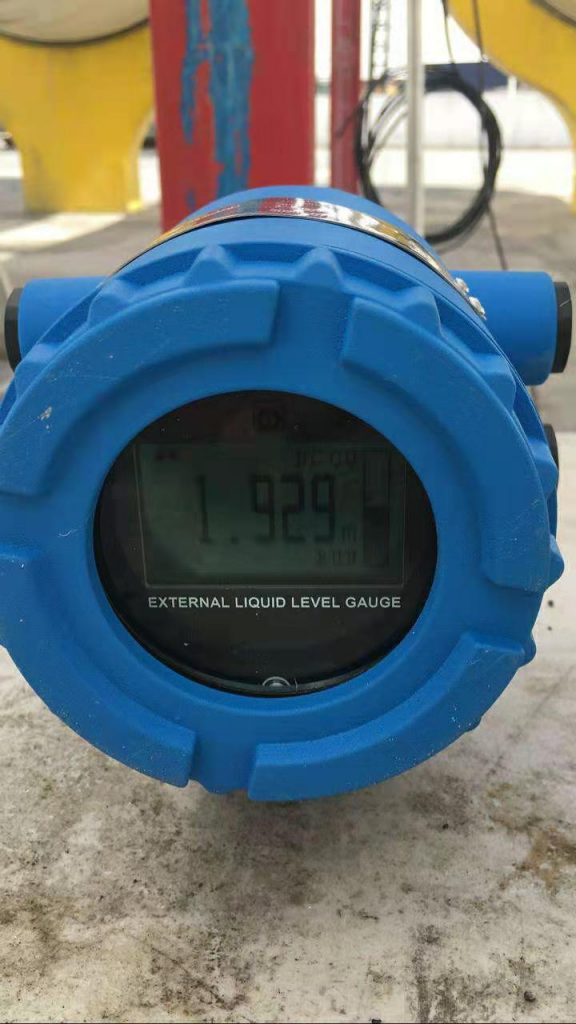

SKE non-invasive level gauge features a truly non-invasive sensing technique; the sensor bonds to the outside of the tank shell; 0..5v / 4…20mA analog output with local display; system approved for hazardous areas which is no problem to install in plant/refinery.

This reliable and accurate tank gauge(mm accuracy) is never affected by pressure, keeps well operated during discharge or inlet; easy installation – no tank break-in; simple retrofit to existing tanks ; no downtime during installation; and no moving parts, therefore no maintenance.