Project Description

Conservator Tank Level Meter

SK-YZ04

BENEFITS

Non-invasive level measurement

Transformer Oil Level in Conservator Tank

Split type design with extension rods

Real-time measuring and display

Specialized for electric power plant

ISO 9001 registered

Conservator Tank – Transformer Oil Level Measurement

Current level measurement for transformer oil conservator tank mostly relies on manual visual inspection, which leads to poor reliability.

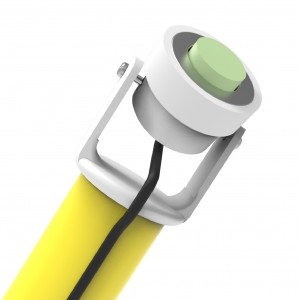

A non-contact online oil level meter is necessary to solve this problem. The sensor is clamped to the outer wall of the conservator tank bottom by a magnet and measures the oil level using the sonar principle.

The output signal is transmitted to the power station acquisition system to realize real-time monitoring of the oil level in the tank, reliable and easy to operate.

Why Choose Sonar Solution?

For sonar measurement, the transformer oil conservator tank level is a relatively simple condition, mainly as follows.

1. The diameter of the transformer oil conservator tank is commonly not large, which means that the measuring range of the monitor is relatively small, so the transmitting circuit requires not much power.

2. Transformer oil is pure (no impurities, precipitation, etc.), with good acoustic performance, the signal in the propagation process attenuation is small, so the receiving circuit is without too much gain.

3. The oil level inside the conservator tank is relatively stationary, the oil-gas interface has good reflection performance on the transmitting wave, the echo amplitude is strong, and the time is stable, so the oil level measurement is very reliable.

Product Stucture

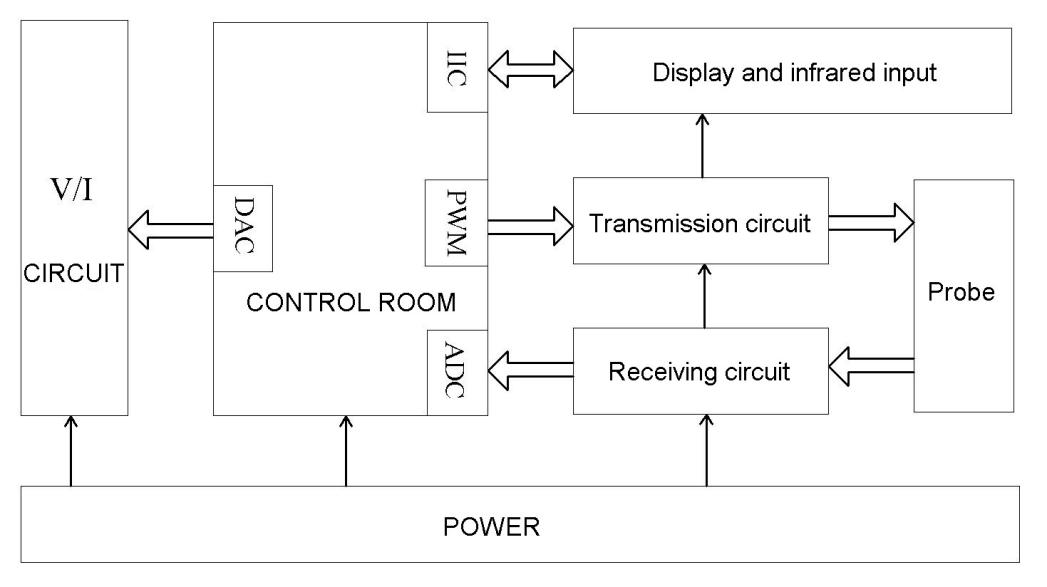

Circuit Design

This solution is including a mainframe and a probe. The main unit includes a transmitter, a receiver, a controller, a display, a power supply, and a V/I conversion circuit.

One end of the transmitting circuit is connected to the controller for receiving the transmit signal from the controller, while the other end is connected to the probe, for transmitting a high-voltage pulse string signal, which generates a sonar wave signal.

The other end of the receiving circuit is connected to the controller’s ADC port. The controller reads the analog return signals and converts them into digital signals for analysis. The controller is also connected to the V/I circuit for outputting a remote 4-20 mA signal.

The display and IR input section is connected to the controller for displaying oil level measurements and adjusting operating parameters. The power supply section supplies power to the entire system.

Application Case