Project Description

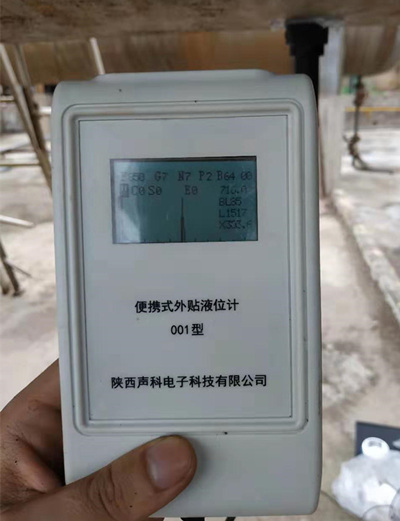

Portable Level Transmitter

SK-PA03

SKE portable level transmitter is designed to offer a simple, accurate, rapid, and reliable method of Liquid level measurement.

It features a truly non-invasive sensing technique.

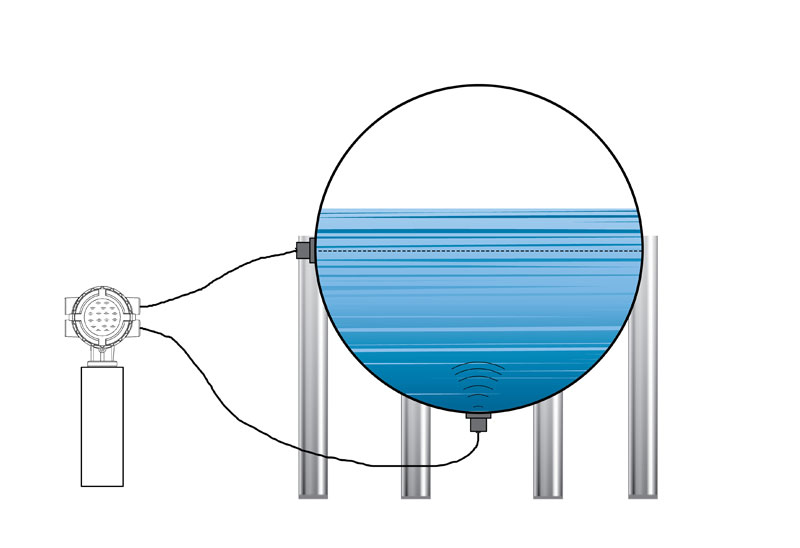

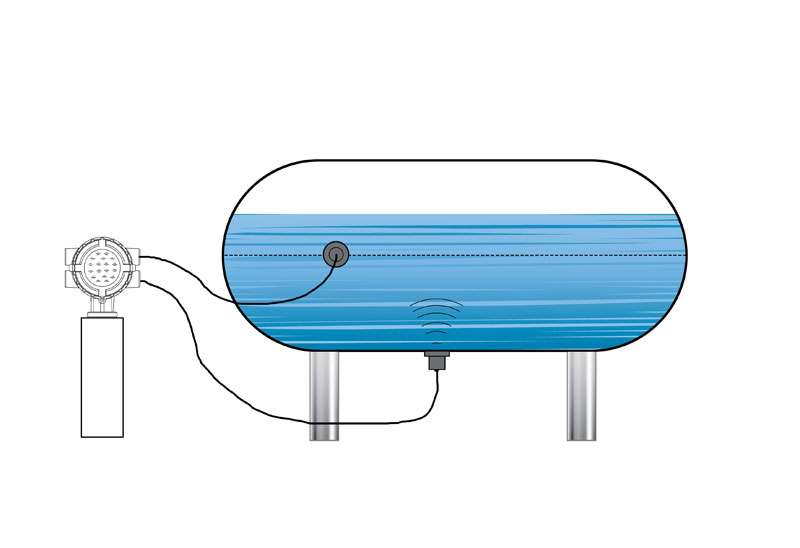

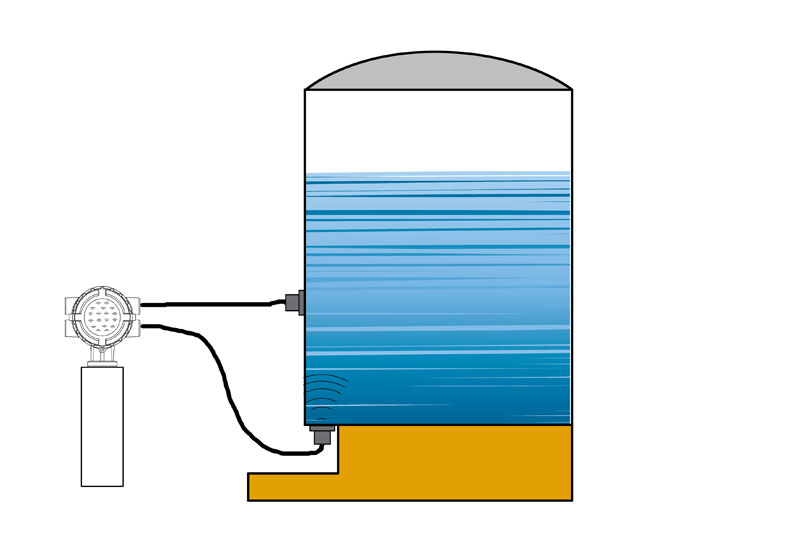

When the magnetic probe is bonded to the bottom shell of the tank, an ultrasonic sound wave travels through the tank and reflects back from the media surface. The system calculates the height of the liquid, from the time taken for the signal to be received.

Signals from the transducers are fed into the processor, then indicate the level on the LCD.

BENEFITS

Portable for walk-around check

No coupling agent required

Real-time display

No moving parts

External Measurement, 100% Safe

Working Principle

The sonar wave signal is emitted from the probe sensor, and the echo signal is detected after being reflected form the liquid surface.

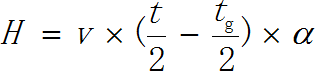

The echo signal is processed by the SKE algorithm then calculate the time “t”, and the system calculates the liquid level according to the formula:

H: The height of the liquid level

t: The time taken by the sonar wave from launch to return

tg: The transmission time of the sonar wave in the tank wall

v: The speed of sonar wave propagating in liquid

α: Correction factor

Non-invasive Level Gauge

The Non-invasive level gauge is in use everywhere where the level of liquids in tanks has to be measured continuously. Application possibilities for radar gauges can be found in almost all areas of industry. Sewage treatment plants and water purification plants in particular, but also other environmental engineering facilities as well as power generating stations now rely on cost-effective radar sensors for continuous level measurement.

Measured substance

In general, the dynamic viscosity of the measured medium is required to be less than 10 MPa. S. When 10 MPa. S < dynamic viscosity < 30 MPa. S, the measure range may be reduced and the blind area may be increased. It cannot be measured when the dynamic viscosity is > 30 MPa. S. (1 MPa. S = 1 CP). There should be no dense bubbles in the liquid; there should not be a large number of suspended substances in the liquid, such as crystals; there should not be a large number of sedimentary substances in the liquid, such as mud and sand. The temperature of the measured medium shall be within – 50 ℃ ~ 100 ℃.

| Butadiene | Propylene | LPG | Propane |

| Liquid ammonia | Methyl alcohol | Methylbenzene | Butadiene |

| 98% sulfuric acid | Diesel | Gasoline | Naphtha |

| Liquid chlorine | Iso-butane | Epoxypropane | Acetone |

| Sulfuretted hydrogen | Styrene | N-butane | Xylene |

| Silicon tetrachloride | Tert-butylamine | Chloroform | Acetaldehyde |

| Hydrogen fluoride | Hydrofluoric acid | Butane | Hydroxy nickel |

The probe sensor must be clamped directly under the container.

This ultrasound liquid level meter can be used on the storage tanks, cylinders, and any Single Layer holding vessel made of Hard Materials.

– For magnetic containers(exp: carbon steel), it is bonded by a magnet, hand-free use.

– For non-magnetic vessels(exp: stainless), use hands to clamp it tightly on the wall.

| Container (Tank/Vessel) | *Single Layer Vessel only, Wall thickness<25mm

*The Tank wall must be made of Hard Materials *No solid obstructions inside the tank from the probe to the liquid surface. |

| Liquid | *Dynamic viscosity < 10 mPa.S. (or cP, 1cP = 1mPa.s)

*The liquid has no large amounts of precipitation, crystals, and dense bubbles inside. |

| Temperature | -45℃~80℃ |

| Max Measuring Range | 5m |

| Blind Spot | 30mm for Ideal working condition |

| Max Tank/Vessel Wall Thickness | 25mm |

| Liquid Viscosity Requirement | <10 mPa.S |

| Repeatable Measurement Error | ±10mm |

| Ambient Temperature for Display | -20℃ ~ +70℃ (-4℉ ~ 158℉) |

| Ambient Temperature for Probe | -45℃ ~ +80℃ (-49℉ ~ 176℉) |

| Environment Humidity | (0%~95%)RH |

| Display Resolution | 128×64 |

| Power Supply | 3.7v Lithium Battery |

| Charge | USB |

| Operating Hours | >12h |

| Meter Dimensions | 160*80*26mm |

| Cable Length | 1.5m |

| Unit Weight | 1.5kg |