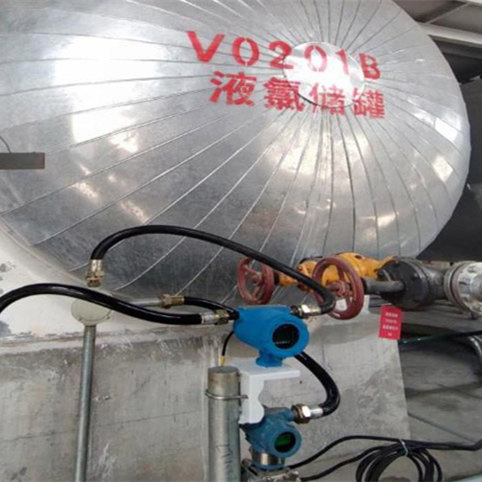

Non-Intrusive Ultrasonic Level Gauge can perfectly solve the level measurement of the liquid chlorine storage tank.

For Liquid Chlorine storage tank, the Non-Intrusive Ultrasonic Level Gauge only needs to stick the probe to the bottom of the tank by magnetic suction. It is easy and safe to install, and there is no need to stop production or drill holes.

Non-Intrusive Ultrasonic Level Gauge can be used in the most demanding environments. Not only can it measure liquids at any pressure, but it can also measure the most toxic liquids, including corrosive liquids, as well as absolutely sterile or extremely pure liquids.

YOUR BENEFIT

Chemical properties of liquid chlorine

- Chemical name: liquid chlorine molecular formula: Cl2

- Molecular weight: 70.91

- liquid chlorine is yellow green oily liquid, toxic

- Specific gravity is 1.4256 at 15 ℃, boiling at – 34.6 ℃ under standard conditions.

- When it solidifies at – 101.5 ℃, it is strongly corrosive to steel in case of water molecules.

Application of liquid chlorine

Liquid chlorine is generally used after gasification and is widely used as a strong oxidant. It is used in bleaching of textile and paper industry, purification and disinfection of tap water, refining of magnesium and other metals, and preparation of various chlorinated compounds such as pesticides, detergents, plastics, rubber, medicine, etc. In chemical production, polyvinyl chloride and chlorinated polyethylene are synthesized from polyethylene and liquid chlorine. Widely used in papermaking, textile, pesticide, organic synthesis, metal smelting, chemical raw materials and other industries, as well as domestic water disinfection

Hazard characteristics of liquid chlorine

Liquid chlorine doesn’t burn, but it can support combustion. Most combustibles can be burned in chlorine, and flammable gases or vapors can form explosive mixtures with chlorine. Chlorine can react violently with many chemicals, such as acetylene, turpentine, ether, ammonia, fuel gas, hydrocarbons, hydrogen, metal powder, etc., and produce explosive substances. It is corrosive to both metals and nonmetals.

Storage of liquid chlorine

A horizontal tank is preferred. Tank farm is basically used for zero hour storage. The horizontal tank is easy to operate and measure. Tank material needs to have low-temperature resistance, high strength, corrosion resistance characteristics, generally choose 16MnR

How to solve the problem of liquid chlorine measurement?

Why choose Non-Intrusive Ultrasonic Level Gauge to measure liquid chlorine tanks?

Type of level gauge used for liquid level measurement

In liquid level measurement, the following types of liquid level meters have a lot of practical applications:

1. Buoyancy level meter

Such as float level gauge, flap level gauge, float level gauge, float plate level gauge, float level gauge, steel belt level gauge.

This type of buoyancy level gauge has measurement accuracy.

However, the site installation and structure is more complex, many mechanical parts, in the practical application process of daily maintenance is very large.

2. Pressure level gauge

Pressure transmitters, single flange level transmitters and plug-in level transmitters are commonly used for level measurements in open containers.

Differential pressure transmitters and remote double-flange differential pressure transmitters are commonly used for liquid level measurements in closed containers.

The differential pressure level gauge is easily affected by medium density and temperature changes in the measurement process, and the maintenance of accessories is very large.

It is expensive to measure the liquid level of a highly corrosive medium.

3. Microwave level meter

Ultrasonic level gauge, radar level gauge and guided wave radar level gauge are microwave level measuring instruments, which can be used for solid and liquid level measurement.

Although these level meters have advanced technology and higher measurement accuracy, they are suitable for pressure vessels storing light hydrocarbons, liquid ammonia and liquid chlorine.

Due to the low dielectric constant, volatility and large number of droplets in the gas phase medium, it will absorb and affect the reflection of electromagnetic waves.

Interference with the liquid level measurement of microwave liquid level meter results in the instability of the measured value of the liquid level meter.