An energy company in Hancheng, Shaanxi Province is mainly engaged in the production and sales of Liquid Ammonia, Crude Methanol, and related products.

The company’s on-site liquid ammonia Spherical Tanks are two liquid ammonia spherical tanks with a measuring range of 12300mm. Due to the early construction of the storage tank,

there is no more spare installation hole for normal level gauge. A set of radar level gauge and a set of magnetic level gauge has been used on-site for a long time.

With the use of a period of time, the anti-corrosion and waterproof coating on the waveguide rod of Leida liquid level gauge is aging, causing the liquid level to jump, At the same time, because the field medium is liquid ammonia, and the medium characteristic of liquid ammonia is that it is seriously gasified by high temperature, which will form a gas-liquid phase.

In summer, the temperature of the magnetic level gauge used at the site is serious, and the liquid level in the magnetic flap tube is seriously gasified.

The difference between the measured liquid level and the actual liquid level is very large. When the liquid level in the tank is still, the difference between the liquid level of the magnetic level gauge in the day and at night is more than 1 m.

With the national management and control of chemical plant safety further strengthened, the chemical plant began to corresponding national safety management requirements to install the SIS safety interlock system,

requiring three sets of remote level gauges to enter the SIS safety interlock system, and one set of on-site display liquid level gauge. The company’s on-site display level gauge has a magnetic level gauge,

while the remote level gauge only has a set of radar level gauge. At the same time, the normal level gauge can not be installed if there is liquid inside of the tanks, and there is no installation hole for contact liquid level gauge,

which makes the site SIS safety interlock system unable to be used.

Other companies can only install one set of non-intrusive ultrasonic level gauge on the spherical tank, but installing two sets of non-intrusive ultrasonic level gauge will cause great interference and can not be used normally.

Through unremitting efforts and experiments of the R & D department, our company has finally developed two sets of non-intrusive ultrasonic level gauge that can be installed on a tank without mutual interference,

thus solving the problem that SIS cannot be used for a long time And inaccurate liquid level.

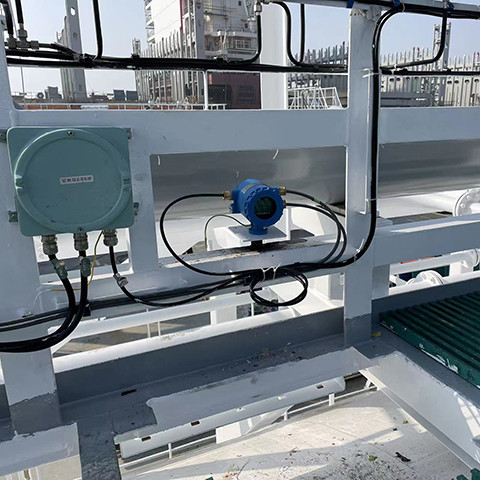

On June 4, 2020, our company installed the non-intrusive ultrasonic level gauges for an energy company in Hancheng, Shaanxi Province. Two sets of non-intrusive ultrasonic level gauge probes were installed on the same horizontal line of the tanks.

The installation was simple and convenient without firework. At the same time, the liquid level value difference between the two sets of SKE level gauges was not more than one centimeter.

Through the software processing, there would be no interference between the two gauges So as to greatly improve the stability of the instrument. On June 5, 2020,

it was officially connected to the SIS safety interlock system with stable operation and high accuracy. Because of the unique temperature calibration of our instrument,

it greatly solves the low-level accuracy problem that other non-intrusive ultrasonic level gauge cannot solve.